The 9-Minute Rule for Steel Road Plates

Wiki Article

Facts About Steel Road Plates Uncovered

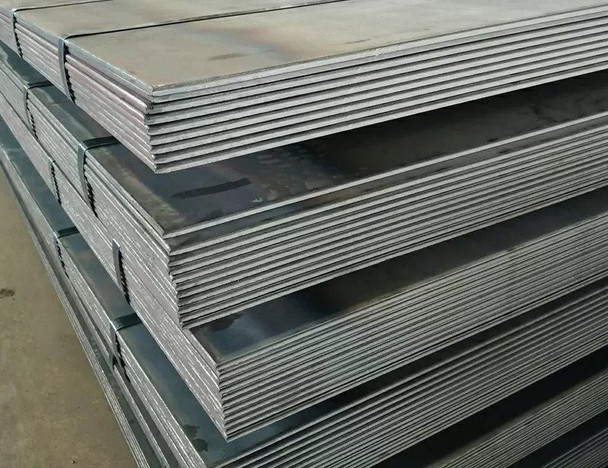

These durable, robust plates permit roadways to return to solution so that building and construction can proceed. These plates can be used to make certain that roadways can still be made use of whilst various other stages of job proceed.They are typically seen when excavations have begun as a very early phase of building and construction or repair work jobs. These plates are designed to stand up to sturdy usage on hectic roadways.

The weights begin from roughly 300kg and conventional roadway plates have a density of either inch or inch. The capability to be bolted to the road.

Get This Report about Steel Road Plates

Hinged variations for fast accessibility to the excavation or normal access, e.g. driveways. Compound plates, which can accommodate various lengths of trench. For this reason, they must be mounted utilizing a forklift or crane.Look for displacement by traffic packing from the beginning plates should constantly resist displacement. Inspect that the plates do not provide a hazard to any kind of sort of road individual and can be made use of by all road customers and automobile kinds, including pedestrians, bikers and motorcyclists. Produce a normal evaluation and maintenance to make sure that efficiency stays risk-free and optimum.

Deal with the plates correctly at all times. Mechanical lifting ensures that the plates are mounted precisely and securely.

If a ramp is created by the road layers, after that advising signs for pedestrian and roadway customers are called for. Always a conduct complete website survey, and take the professional suggestions of a structural engineer. The Department of Transport likewise provides advice on setting up road plates, please go here. SafeSite Facilities (Steel road plates)' roadway plates are offered for buy or hire throughout the UK.

Some Of Steel Road Plates

In order to improve security, there are a variety of standards and market files directing their usage in building and construction work areas. This article gives some highlights that might be useful in starting your examination. If you need additional info, please get in touch with our expert directly. Steel plates must be dealt with in position to avoid movement.

Our Steel Road Plates Statements

In addition to being securely touching the sidewalk, they must be either pinned, recessed into the pavement, or safeguarded with asphalt wedges around the boundary. Pinning into the sidewalk involves driving pins right into the sidewalks along the sides of the steel plates to avoid activity. Recessing includes Check Out Your URL cutting out the area where the steel plate will be positioned.

This causes the steel plate being flush with the sidewalk. In addition, when multiple steel plates are utilized and butt approximately each get redirected here various other, they should be welded together at the longitudinal joints. Steel plates can be extremely slippery, specifically when they are damp, unless they have an anti-skid coating applied.

Treatment steel plates with a material that enhances friction helps motorcyclists and bicyclists keep control, particularly in wet weather condition. Problems which minimize pavement friction in work zones are of specific concern to motorcyclists and bicycles. A typical hazard in steel plate installments takes place when the customer falls short to build effectively tapered ramps from the street to the edges of the steel plate( s).

Steel Road Plates Can Be Fun For Everyone

It postures a substantial risk to motorcyclists and bicyclists that can quickly blow up when they call the abrupt/steep tapered ramp and the steel plate. Properly tapered ramps allow users to safely go across over the steel plates. Tapers for steel plates are normally constructed of asphalt. The taper sizes vary from State to State and generally variety from 20 to 1 to 120 to 1 (Steel road plates).Ensure sufficient overlap. Typically, steel plates have to expand at least one foot beyond the pavement opening onto company ground.

An Unbiased View of Steel Road Plates

Welding is used when greater than one steel plate is used and they butt approximately each other. Plates must be countersunk when required because of irregular highways. Plates need to be coated with an official source anti-skid coating. The sides of the steel plates need to be marked/painted to enhance presence. Proper advance indication should be made use of.

His background includes the building and construction, inspection, learn more.

On the planet of civil design and building, steel roadway plates are a quintessential device that holds enormous importance. These sturdy steel plates play an essential function in enhancing building security, giving short-lived streets, and ensuring smooth procedures on various task sites. As a construction devices vendor, their relevance can not be overemphasized.

Report this wiki page